A wood boiler or biomass boiler can be a great choice for your home. Of course, it's important to do your due diligence when considering an investment as important as your home heating system. One crucial aspect to consider is the boiler's longevity.

Uniquely, boilers are constantly exposed to water and fire. Boilers must therefore resist both heat and the possibility of corrosion. Thermal or water leaks often mean the end of safe and/or useful boiler life.

How Long Can an Indoor Boiler Last?

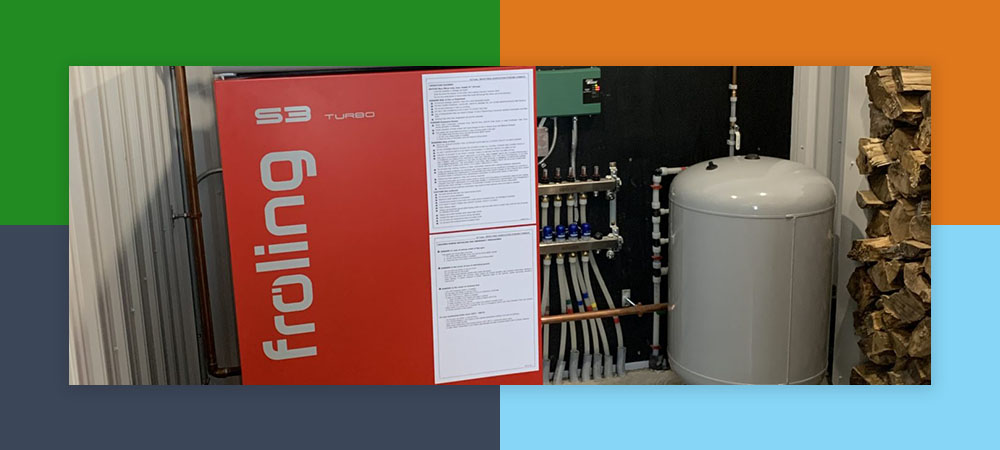

Indoor wood boilers can last 40 years or longer when properly maintained and operated. Many boilers that Tarm USA supports were originally sold in the 1970s. Modern indoor wood boilers, often called 2 stage or gasification boilers, last far longer when paired with heat storage tanks and are batch burned. Batch burning eliminates corrosive condensate inside the firebox.

How Long Can an Outdoor Boiler Last?

Outdoor boilers typically do not last longer than 20 years. Outdoor wood boilers are subjected to harsh exterior weather. Even condensation from changing outside temperatures can lead to water accumulating on exterior surfaces and corroding the water jacket. Internally, moisture and ashes that accumulate during the smoldering process between heat demands cause corrosion inside the firebox.

When indoor and outdoor boilers are filled with other than pure wood, more damage can result. wood that has been chemically treated or wood, which has been soaked in the ocean can cause rapid corrosion. Burning garbage introduces chemicals of unknown impact.

Boiler Material is important

Boilers are made from a variety of metals. Carbon steel, stainless steel, and cast iron are the most common boiler materials. In highly corrosive boiler operation, such as in outdoor wood boilers, where oxygen is present in the water, or in condensing gas boilers, where corrosive exhaust gasses can accumulate, stainless steel is a preferred boiler material. Some outdoor wood boilers use carbon steel and require that a regimen of oxygen scavenging chemicals is added to the boiler water. Carbon steel and cast iron are good materials for closed loop, pressurized hot water boilers. Most indoor wood boilers are pressurized. While stainless steel has high corrosion resistance, thermal expansion, brittleness, and reduced heat transfer are downsides of stainless steel in boilers. Carbon steel is thermally more stable, is more flexible, and conducts heat better than stainless steel, so in environments where corrosion is minimized, carbon steel is a preferred boiler material. Indoor wood boilers are almost always pressurized. Pressurization eliminates oxygen in the water, so carbon steel is preferred. Cast iron is rarely used in wood boilers anymore due to impracticality of large castings that would be required.

A Boiler's Useful Life - The Average Life of a Boiler

Some boilers remain in use for decades. However, available replacements may be far more efficient, safer, and easier to use. It doesn't always make economic sense to keep using a boiler because it has not yet failed. In some cases, the useful life of a boiler may be only 10-15 years. Technology advances may determine when it is time to upgrade rather than boiler failure. It is always better to have a planned replacement than an emergency replacement.

How to Extend Your Boiler's LifeSpan

Indoor and outdoor wood boilers can exceed expectations for boiler life expectancy with enough love and care. Here are some of the most important elements of a wood boiler maintenance routine.

-

- Install and operate boilers as per the owner's manual: Many people may never read the owner's manual provided with their wood boiler. Many manuals contain "boiler plate" language required by code authorities, which may seem boring or useless. Manufacturers put a great deal of effort into writing manuals for the benefit of the operator. Heeding manufacturer's instructions can ensure long boiler life.

- Fill new boilers with clean water: Ensure boiler water has low chlorides, low turbidity, and a pH that is safely above neutral.

- Burn only materials allowed by the manufacturer.

-

- For outdoor wood boilers, use Rust inhibitor treatments: Add a rust inhibitor during installation as per the owner's manual. Be sure to maintain chemicals to prevent corrosion.

- Cleaning: Clean your wood burner regularly as per the owner's manual.

- Summer Ash removal: Avoid letting ash sit in the boiler during the summer. Chlorides in the ash attract moisture, making a highly corrosive environment.

- Eliminate oxygen in boiler water: Make sure the boiler remains pressurized at all times. Keep air vents in working order. Repair leaks to reduce new oxygen from being added to the boiler with fresh "make-up" water.

- Repair leaks: Leaks on the outside of a boiler are not immediately damaging to a boiler, however, over time a leak can lead to corrosion which is difficult to repair.

- Maintain combustion parts, gaskets, and heat shields: Wear parts in a boiler wear due to extreme heat and abrasion. Keeping boiler parts in good working order protects the boiler vessel itself.

- Professional Maintenance: When possible, have regular, annual maintenance performed by a knowledgeable professional. Not only will the boiler last longer, but the boiler will be safer.

- Avoid overheating events: Install heat protection devices as per the owner's manual. Overheating boilers damages controls, gaskets, and can even damage the boiler vessel itself, especially if the vessel runs dry.

- Make sure the boiler is the right size: Boilers that are too large can smolder and create corrosive creosote. Boilers that are too small can operate for more than the designed/anticipated number of hours per year and may not last as long.

Choose Boilers From Tarm Biomass

Tarm Biomass is the top source for reliable indoor wood boilers that provide consistent warmth. You can learn more about our wood boilers online or get in touch with us to discuss how a wood boiler will benefit your home.